What is the New Scheme?

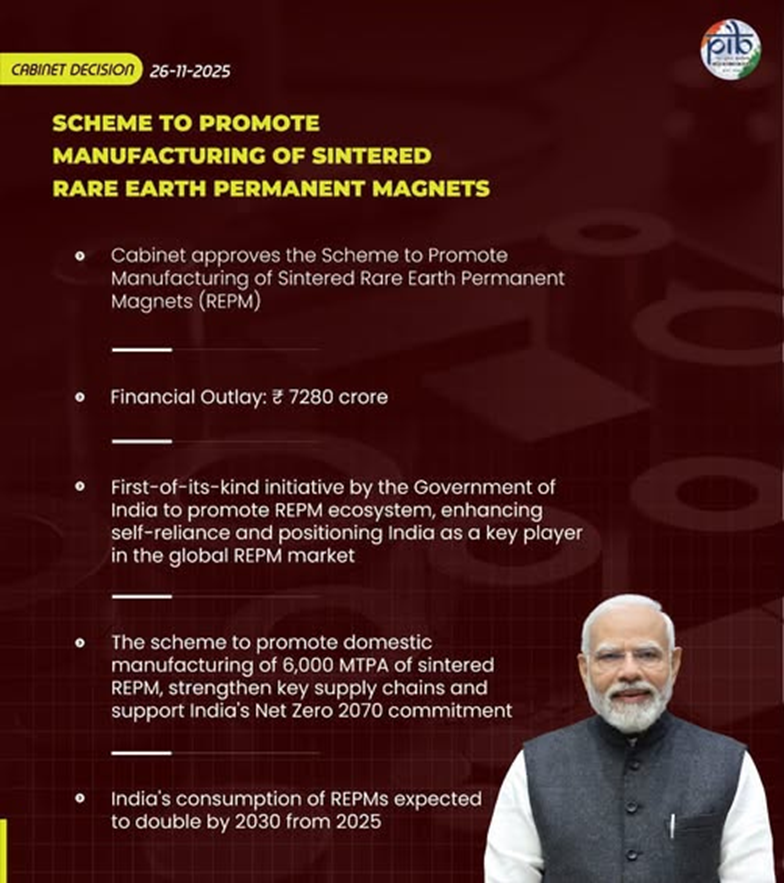

- Approval: The Union Cabinet has approved the ‘Scheme to Promote Manufacturing of Sintered Rare Earth Permanent Magnets’ (REPM).

- Strategic Goal: To establish a domestic capacity of 6,000 Metric Tonnes Per Annum (MTPA) of integrated REPM manufacturing.

- First-of-its-Kind: This initiative marks India’s entry into the complete value chain converting rare earth oxides to metals, metals to alloys, and alloys to finished magnets.

SCHEME AT A GLANCE

2. Key Features & Financials

- Total Outlay: ₹7,280 Crore.

- Incentive Structure:

- Sales-Linked Incentives: ₹6,450 Crore (disbursed over 5 years).

- Capital Subsidy: ₹750 Crore for setting up facilities.

- Beneficiaries: 5 entities will be selected via global competitive bidding (max capacity of 1,200 MTPA each).

- Duration: 7 Years total (2-year gestation period for plant setup + 5 years for incentive disbursement).

INDIA’S LEAP INTO CRITICAL MINERALS: THE REPM SCHEME

1. What is the New Scheme?

- Approval: The Union Cabinet has approved the ‘Scheme to Promote Manufacturing of Sintered Rare Earth Permanent Magnets’ (REPM).

- Strategic Goal: To establish a domestic capacity of 6,000 Metric Tonnes Per Annum (MTPA) of integrated REPM manufacturing.

- First-of-its-Kind: This initiative marks India’s entry into the complete value chain—converting rare earth oxides to metals, metals to alloys, and alloys to finished magnets.

SCHEME AT A GLANCE

2. Key Features & Financials

- Total Outlay: ₹7,280 Crore.

- Incentive Structure:

- Sales-Linked Incentives: ₹6,450 Crore (disbursed over 5 years).

- Capital Subsidy: ₹750 Crore for setting up facilities.

- Beneficiaries: 5 entities will be selected via global competitive bidding (max capacity of 1,200 MTPA each).

Duration: 7 Years total (2-year gestation period for plant setup + 5 years for incentive disbursement).

3. What are Rare Earth Permanent Magnets (REPM)?

- Definition: Permanent magnets manufactured from alloys of rare earth elements.

- Key Properties:

- High Magnetic Strength: Significantly stronger than standard ferrite or alnico magnets.

- Resistance: High resistance to demagnetization.

- Efficiency: Offers superior performance-to-size ratio, essential for miniaturization.

4. Major Types & Applications

- Neodymium Iron Boron (NdFeB):

- Composition: Neodymium, Iron, and Boron.

- Trait: The strongest commercially available permanent magnet.

- Uses: Electric Vehicle (EV) motors, hard disk drives, and consumer electronics.

- Samarium Cobalt (SmCo):

- Composition: Samarium and Cobalt.

- Trait: Excellent thermal stability and corrosion resistance; retains magnetism at high temperatures.

- Uses: Aerospace, defence systems, and high-speed motors.

5. Strategic Applications

- Green Energy: Vital for wind turbine generators.

- Mobility: Critical for traction motors in Electric Vehicles (EVs).

- Defence: Used in guidance systems, radar, and actuators.