After reading this article you can solve this UPSC Mains Model question:

Rare earth minerals are often described as the “oil of the 21st century”. Examine this statement in the context of their strategic uses, supply-chain vulnerabilities, and India’s policy response. Suggest a way forward to achieve technological and strategic autonomy. (GS-1 Geography)

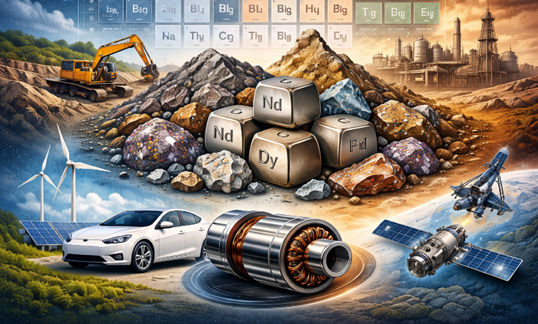

What are Rare Earth Minerals?

Rare Earth Elements (REEs) are a group of 17 chemical elements in the periodic table, specifically the 15 lanthanides plus scandium and yttrium.

- Nature: Contrary to their name, they are relatively abundant in the Earth’s crust. However, they are “rare” because they are typically found in low concentrations and are difficult to extract and separate from one another.

- Classification:

- Light REEs (LREEs): Lanthanum, Cerium, Neodymium, Praseodymium (abundant in India).

- Heavy REEs (HREEs): Dysprosium, Terbium (scarce in India; often imported).

Examples and Key Minerals

A. Key Rare Earth Elements & Their Uses

| Element | Category | Major Uses / Importance |

| Neodymium (Nd) | LREE | Strong permanent magnets (EV motors, wind turbines, smartphones) |

| Praseodymium (Pr) | LREE | Aircraft engines, magnets, glass colouring |

| Lanthanum (La) | LREE | Camera lenses, battery electrodes (NiMH batteries) |

| Cerium (Ce) | LREE | Catalytic converters, glass polishing powders |

| Samarium (Sm) | LREE | High-temperature magnets, defence applications |

| Europium (Eu) | HREE | Red phosphors in LED, TV and display screens |

| Dysprosium (Dy) | HREE | Heat-resistant magnets (EVs, missiles) |

| Terbium (Tb) | HREE | Green phosphors, solid-state devices |

| Yttrium (Y) | HREE | Laser systems, superconductors, medical imaging |

| Scandium (Sc) | (REE) | Lightweight aluminium alloys, aerospace components |

B. Important Rare Earth–Bearing Minerals

| Mineral | Key Features | Significance |

| Monazite | Phosphate mineral rich in LREEs; found in beach sands | Primary REE source in India (also contains thorium) |

| Bastnäsite | Carbonate mineral rich in Ce, La, Nd | Major global source (China, USA) |

| Xenotime | Phosphate mineral rich in HREEs | Important for heavy rare earth supply |

| Ion-adsorption clays | Weathered clay deposits | Major source of HREEs (environmentally sensitive) |

Strategic Uses of Rare Earth Minerals:

Rare earth minerals are termed “strategic” because they underpin national security, economic competitiveness, and energy transition.

1. Defence & National Security

- Precision-guided missiles: Neodymium–dysprosium magnets for guidance and control systems.

- Radar & sonar systems: Yttrium, gadolinium improve signal accuracy.

- Jet engines & military aircraft: Samarium-cobalt magnets withstand high temperatures.

- Secure communications & night-vision devices: Europium, terbium phosphors.

2. Clean Energy & Energy Transition

- Wind turbines: Neodymium-based permanent magnets enable high efficiency and low maintenance.

- Electric vehicles (EVs): Motors rely on Nd-Pr-Dy magnets for compactness and power density.

- Energy-efficient lighting: Europium and terbium in LEDs.

3. Space & Advanced Technology

- Satellites and spacecraft: Rare earth alloys for lightweight, heat-resistant components.

- Solar panels in space missions: Enhanced efficiency using REE coatings.

- Laser systems: Yttrium-aluminium garnet (YAG) lasers for defence and research.

4. Electronics & Semiconductor Industry

- Smartphones, laptops, servers: Miniaturised magnets, capacitors, and displays.

- Semiconductor fabrication: Cerium for wafer polishing; lanthanum for high-k dielectrics.

- Data centres & AI hardware: Cooling systems and precision components.

5. Nuclear & Energy Security

- Nuclear reactors: Control rods and shielding materials (samarium, gadolinium).

- Thorium-linked rare earth minerals: Strategic for future nuclear fuel cycles.

6. Medical & Critical Infrastructure

- MRI scanners & imaging: Gadolinium contrast agents.

- Advanced surgical lasers & diagnostics: Yttrium-based technologies.

The Process: From Sand to Magnet:

The process is generally divided into Upstream, Midstream, and Downstream stages:

1. Upstream: Mining and Concentration

- The Source: In India, the primary source is Monazite sand (found in coastal “heavy mineral sands”).

- Physical Separation: Ores are processed using gravity, magnetic, and electrostatic separation to create a Mineral Concentrate.

2. Midstream: The Refining “Bottleneck”

This is where India currently faces its greatest challenge. China controls ~90% of this stage.

- Cracking & Leaching: The mineral concentrate is treated with chemicals (caustic soda or sulfuric acid) to “crack” the mineral structure.

- Solvent Extraction: This is a repetitive, multi-stage chemical process where mixed rare earth solutions are passed through hundreds of tanks to separate individual elements (like Neodymium from Cerium) based on their slight chemical differences.

- Oxide to Metal: The separated Rare Earth Oxides (REOs) are then reduced to pure Rare Earth Metals using high-temperature electrolysis or metallothermic reduction.

3. Downstream: Magnet Manufacturing

The government’s new ₹7,280-crore scheme focuses on creating Sintered NdFeB (Neodymium-Iron-Boron) Magnets:

- Alloying: Pure Neodymium metal is melted with Iron and Boron in a Vacuum Induction Melting (VIM) furnace to create an alloy.

- Milling (Jet Milling): The alloy is ground into a microscopic powder (about 3-5 microns—finer than a human hair).

- Orientation & Pressing: The powder is placed in a mold. A strong magnetic field is applied to align the particles (orientation), and the powder is then pressed into a solid block (“green compact”).

- Sintering: The blocks are heated in a vacuum furnace to just below their melting point. This fuses the particles into a dense, solid magnet.

- Finishing: The magnets are machined to size, coated (usually with Nickel or Zinc) to prevent corrosion, and then finally Magnetized.

Challenges:

1. Midstream Refining: The “Missing Link”

- Technological Monopoly: China controls over 90% of global rare-earth processing. India currently mines these minerals but lacks the commercial-scale solvent extraction technology needed to separate mixed rare earth oxides into individual, high-purity elements.

2. Regulatory and Nuclear Governance

- The Monazite-Thorium Link: India’s primary REE source is monazite sand, which is naturally radioactive because it contains Thorium (essential for India’s Three-Stage Nuclear Program).

- Dual Oversight: This subjects the sector to a “punctilious governance regime.” Projects must be coordinated between the Ministry of Mines and the Department of Atomic Energy (DAE), leading to longer gestation periods (often 10–15 years from exploration to production).

3. Geopolitical “Managed Scarcity”

- Licensing as Leverage: While China has recently issued a few export licenses for magnets to Indian firms (including suppliers for Maruti and Mahindra), these are being released as a “trickle.”

- Dependence Risk: This creates “managed scarcity,” where Indian manufacturers remain operationally constrained by administrative delays in Beijing rather than market availability.

4. Environmental and Social Challenges

- Green Compliance: Extracting REEs is chemically intensive. For every tone of rare earth produced, the process generates roughly one tone of radioactive residue and massive amounts of toxic wastewater.

- Coastal Sensitivity: Much of India’s reserves are in fragile coastal belts (e.g., Andhra Pradesh and Kerala). Mining risks shoreline erosion and threatens the livelihoods of local fishing communities, leading to social friction and litigation.

5. Economic and Market Barriers

- Price Volatility: China’s ability to “modulate” global prices can make Indian domestic projects unviable overnight.

- Investment Risk: Sintered magnet manufacturing requires high precision—automotive-grade magnets require ±2°C temperature tolerance during sintering. This technical barrier makes projects high-risk for private investors without heavy government subsidies.

Government Initiatives:

1. REPM Manufacturing Scheme (The “Magnet PLI”)

- Outlay: ₹7,280crore over 7 years.

- Objective: To establish an integrated ecosystem for Sintered Rare Earth Permanent Magnets (REPM).

- Components:₹6,450crore in sales-linked incentives (incentivizing the sale of finished magnets).

- ₹750crore in capital subsidies for setting up facilities.

- Target: Create a domestic capacity of 6,000 Metric Tonnes Per Annum (MTPA), enough to meet nearly 50% of projected demand for EVs and wind turbines by 2030.

2. National Critical Mineral Mission (NCMM) 2025

- Outlay: Total expenditure of ₹34,300crore (including ₹18,000 crore from PSUs).

- Core Goals:

- Exploration: GSI has been tasked with 1,200 exploration projects by 2030.

- Processing Parks: Setting up dedicated zones for refining and solvent extraction.

- Stockpiling: Developing a national strategic reserve of REOs to buffer against global supply shocks.

- Recycling: A ₹1,500 crore incentive to recover REEs from e-waste and end-of-life EV batteries (“Urban Mining”).

3. MMDR Amendment Act, 2025

- Mineral Exchanges: Statutory recognition for electronic platforms to trade minerals/metals, ensuring price transparency and preventing cartelization.

- One-Time Extension: Existing leaseholders can extend their areas by up to 10–30% for deep-seated/critical minerals.

- NMEDT: The National Mineral Exploration Trust was renamed the National Mineral Exploration and Development Trust, with its funding scope expanded to include the development of mines and international projects.

4. Global Mineral Diplomacy (KABIL)

- Joint Venture: Khanij Bidesh India Ltd (KABIL) is aggressively acquiring assets abroad.

- Acquisitions: In 2025, KABIL moved beyond Lithium to explore HREE (Heavy Rare Earth) blocks in Australia and Zambia to supplement India’s domestic LREE-heavy reserves.

- MSP Participation: India is an active member of the Minerals Security Partnership, a US-led club aiming to build “China-plus-one” supply chains.

Way Forward:

1. Bridging the “Midstream” Gap

- Integrated Hubs: Establishing “Critical Mineral Processing Parks” where raw oxides can be refined into 99.9%+ pure metals.

- Technology Licensing: Partnering with countries like Japan and Australia to acquire proprietary solvent extraction technology—the current global bottleneck.

2. Scaling “Urban Mining” (Circular Economy)

- Secondary Recovery: Incentivizing startups to recover Neodymium and Dysprosium from end-of-life EV batteries and electronic scrap.

- Policy Target: The ₹1,500 crore recycling incentive aims to recover 40,000 tonnes of critical minerals from waste by 2030, reducing the environmental footprint of traditional mining.

3. Strategic Stockpiling & Demand Assurance

- National Buffer: Following the US and Japanese models, the National Critical Mineral Mission (NCMM) plans to build a strategic stockpile to protect domestic manufacturers from Chinese export shocks and price volatility.

- Offtake Agreements: The government can act as a “market-maker” by guaranteeing long-term purchase orders for strategic sectors like Defense and Space, giving private investors the confidence to build expensive magnet plants.

4. Regulatory Streamlining

- Single-Window Clearance: Merging the approval processes of the Ministry of Mines and the Department of Atomic Energy (DAE) to reduce the time from “discovery to production” (currently 10–15 years).

- Private Participation: Encouraging private firms to enter monazite mining while maintaining strict radiation safety protocols for thorium management.

5. Mineral Diplomacy and “Friend-Shoring”

- MSP and KABIL: Strengthening participation in the Minerals Security Partnership (MSP) and leveraging KABIL to acquire Heavy Rare Earth (HREE) assets in Australia, Zambia, and Argentina. This ensures a balanced supply of both Light and Heavy REEs.

Conclusion:

While 20th-century power was defined by who controlled the flow of oil, 21st-century power will be defined by who controls the processing of rare earths. For India, the conclusion is clear: Strategic Autonomy in the digital and green era requires domestic refining capacity, innovation in magnet-free technologies, and a robust “urban mining” ecosystem.