Why In the News?

- The Government of India announced the National Manufacturing Mission (NMM) in the Union Budget 2025–26, which specifically emphasizes transitioning Indian industries toward Industry 5.0 paradigms.

- This shift aims to integrate human creativity with advanced automation to meet India’s “Net-Zero 2070” commitments and bolster the “Make in India” initiative through sustainable and resilient manufacturing.

1. Overview of Industry 5.0

Industry 5.0, also known as the Fifth Industrial Revolution, is a conceptual framework that reintroduces the “Human Touch” into the highly automated world of Industry 4.0. While the previous revolution focused on interconnectivity and efficiency through Artificial Intelligence (AI) and the Internet of Things (IoT), Industry 5.0 focuses on the symbiotic relationship between man and machine.

2. The Three Core Pillars

Industry 5.0 stands on three foundational legs:

- Human-Centricity: It shifts the focus from “technology-driven” to “human-driven.” Machines are used to empower workers rather than replace them, focusing on worker well-being, safety, and privacy.

- Sustainability: It moves beyond simple productivity to focus on the Circular Economy. This includes resource efficiency, waste reduction (Waste to Wealth), and reducing the carbon footprint of industrial processes.

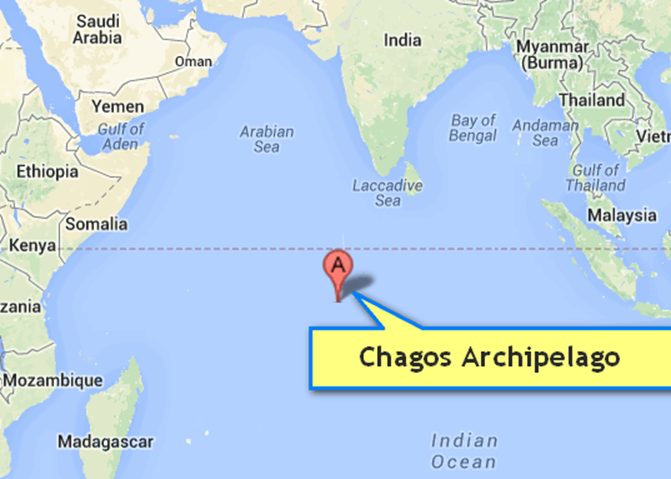

- Resilience: It emphasizes the ability of industrial production to withstand disruptions, such as pandemics (COVID-19) or geopolitical tensions, through agile and flexible supply chains.

3. Comparison: Industry 4.0 vs. Industry 5.0

| Feature | Industry 4.0 | Industry 5.0 |

| Primary Focus | Automation and Efficiency | Human-Machine Collaboration |

| Goal | Smart Factories & Connectivity | Sustainability & Worker Well-being |

| Production | Mass Production | Mass Customization |

| Human Role | Monitoring and Oversight | Creativity and Decision-making |

| Technology | IoT, Big Data, AI | Cobots (Collaborative Robots), 6G, Biotech |

4. Key Technologies Driving Industry 5.0

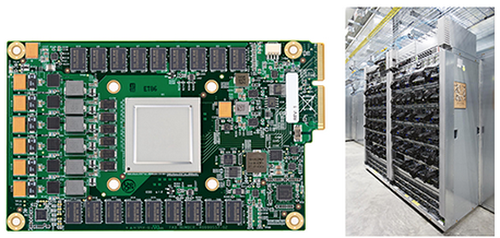

- Collaborative Robots (Cobots): Unlike traditional industrial robots that operate in cages, cobots are designed to work safely alongside humans in a shared workspace.

- Digital Twins: Virtual replicas of physical assets used for real-time monitoring and “what-if” scenario testing to improve resilience.

- 6G and Edge Computing: Providing the ultra-low latency required for real-time human-machine interaction.

- Bio-inspired Technologies: Integration of smart materials and synthetic biology into manufacturing processes.

5. Indian Initiatives & Policy Support

- National Manufacturing Mission (NMM) 2025-26: Launched to synchronize policy across ministries with a focus on clean-tech and Industry 5.0.

- SAMARTH Udyog Bharat 4.0: An initiative by the Ministry of Heavy Industries to push for the adoption of Industry 4.0/5.0 solutions in MSMEs.

- Production Linked Incentive (PLI) Schemes: Incentivizing high-tech manufacturing in sectors like electronics and drones.

- Special Campaign 5.0 (PIB): Focused on institutionalizing “Swachhata” and “Waste to Wealth” models in industrial departments.

Q. With reference to 'Industry 5.0', consider the following statements:

1. It marks a shift from a focus on economic value to a broader concept of societal value and worker well-being.

2. Unlike Industry 4.0, Industry 5.0 aims to replace human workers with fully autonomous AI systems to eliminate human error.

3. One of its core principles is 'Resilience', which focuses on the ability of industries to adapt to sudden supply chain disruptions.

Which of the statements given above is/are correct?

A) 1 and 2 only

B) 2 and 3 only

C) 1 and 3 only

D) 1, 2 and 3

Answer: C

Solution:

STATEMENT 1 CORRECT: Industry 5.0 is fundamentally human-centric, prioritizing the well-being of the workforce and societal benefits alongside profit.

STATEMENT 2 INCORRECT: This statement describes a misconception. Industry 5.0 specifically focuses on human-machine collaboration (using Cobots) rather than replacing humans. It is Industry 4.0 that leaned more toward full automation.

STATEMENT 3 CORRECT: Resilience is one of the three pillars of Industry 5.0, emphasizing agility in the face of global crises.